Scaling brands need control and predictability. China still gives you the widest factory base, fast product tweaks, and strong value for money. 2025 data supports keeping China as your sourcing home. Factory activity returned to slight expansion, with the Caixin China Manufacturing PMI around 50.4–50.5 in mid 2025, which signals steady operating conditions and available capacity for scale. Purchasing and production trends remained near the growth threshold across the summer, keeping supplier networks active and responsive.

You already have demand. Keep China as your base, use clear specs and early QC, and this playbook will turn ideas into repeatable production with fewer surprises.

You already have demand. Use this guide to turn ideas into repeatable production with fewer surprises.

What Are the Benefits of Sourcing from China?

Large supplier choice

You can find multiple factories in most consumer categories. That lets you compare prices, quality, and capacity instead of forcing one supplier to fit all needs.

Fast move from idea to production

With a clear spec, many factories can make a first sample in days. You can test materials, colors, and packaging without losing your launch window.

Flexible price and quality tiers

Build good, better, best versions of the same SKU. Adjust materials and finish to hit different price points while keeping one core design.

Value added work at the source

Kitting, bundles, labels, gift boxes, and simple compliance checks can happen before export. This cuts rework later and lowers damage.

Lower setup cost in many categories

For items that need molds or print plates, tooling often costs less. Your payback on new SKUs is faster.

Mature export process

Factories and forwarders ship to the United States and Europe every day. Paperwork and carton marks are familiar, which reduces avoidable delays.

Scale when demand spikes

Suppliers can add shifts or a second line. A China 3PL can stage urgent air shipments while bulk replenishment sails.

Better packaging for margin

Right size cartons and stronger inner packs reduce damage and keep chargeable weight in check for air.

Stable landed cost after setup

Once you fix specs, QC steps, and routing, costs settle. You can price with confidence and plan promos.

How Lansil Global applies this

We use our China hub to shortlist suppliers, run factory audits, manage samples, and perform AQL checks. For U.S. sellers, we move bulk shipments by sea, fly urgent units when needed, and stock inventory in our Pennsylvania and Nevada warehouses for fast 2 to 4 day delivery.

How to Source Products from China

Treat sourcing as a loop. You will run the same steps each cycle and get faster each time.

- Lock the spec. Write a one page spec that lists materials, finish, key dimensions, tolerances, color codes, packaging style, labeling, and required tests for each market. Add three to five critical quality points with pass ranges. Example for a stainless bottle: 304 steel body, leak test 10 minutes, drop test from 1 meter, dishwasher safe top rack, color PMS 299 C.

Why it matters: clear specs produce clean quotes, fewer mistakes, and a better first sample. - Build a longlist. Collect 10 to 20 suppliers from platforms, trade shows, and referrals. Score them on product focus, export history to your region, response time, and willingness to share documents. Remove suppliers who cannot meet your MOQ or timeline.

Why it matters: a tight longlist saves time and reduces back and forth. - Screen fast with one RFQ format. Send the same RFQ to each supplier. Ask for unit price, tooling, sample lead time, mass lead time, and a simple cost split by materials, labor, packaging, overhead, and margin. Request quotes on the same Incoterms so you can compare.

What to look for: clear math, honest lead times, and questions that show they read your spec. - Run due diligence and audits. Do a desk audit first. Ask for business license, tax data, and bank account name that matches the company. For finalists, run a site audit. Check incoming inspection, work instructions, calibration, in-process checks, final QC, carton labels, and rework steps. If you ship to kids or handle batteries or liquids, confirm specific controls.

Why it matters: QIMA reported higher audit demand in 2024. Early checks prevent costly fixes later. - Sample with intent. Order two samples. One off the shelf to judge base workmanship. One pre production to your spec. Test like a buyer would. Do drop tests for packaging, wash tests for textiles, cycle tests for hinges or zips, and basic compliance checks. Approve a golden sample and keep a change log. Mark each change with date and photo.

Tip: pay for samples. It keeps timing honest and shows you are serious. - Negotiate protection, not only price. Tie payments to quality gates. A common setup is 30 percent deposit and the balance after a passed final inspection. Confirm who owns tools and where they are stored. Add change control. No change to material, finish, or process without written approval. Define the actions if defects exceed your AQL, such as rework time or price credits.

- Run a pilot order. Start with a small order. Hold a pre production meeting to lock materials and timing. Do a during production check at about 50 percent. Finish with a final random inspection against your golden sample and AQL plan. Ship only after a pass.

Why it matters: a pilot shows true lead time and real defect modes before you scale. - Scale with rhythm. Move to a rolling 12 week forecast and reorder triggers by SKU. Standardize a checklist per SKU. Track first pass yield and defect types by lot. Plan cost downs through packaging tweaks, material swaps that still pass tests, or partial line automation.

How to Find Reliable Suppliers in China

Desk check

Verify legal name, license, address, and export records. Read certificates for scope and expiry. Ask which sub suppliers make critical parts.

Short call

Confirm process steps, daily capacity, shift count, and backup plans. Ask what goes wrong most and how they prevent it. You want clear answers, not perfect slides.

Trial build

A pilot reveals more than long emails. See how they handle change notes, QC feedback, and dates.

Ongoing monitoring

Set an audit plan that fits risk. Raise sampling during launches, peak season, or after any change to materials or sub suppliers.

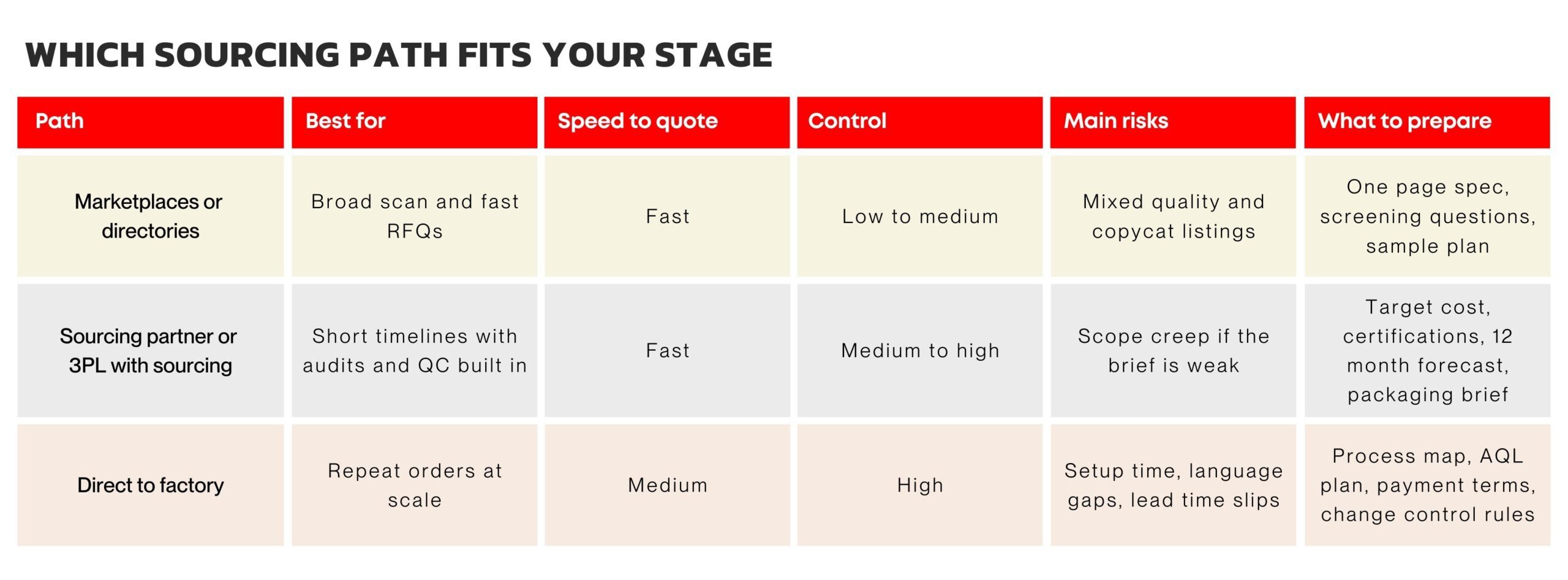

What Is the Best Site to Source Products from China?

There is no single best site. Use each for its strength.

- Alibaba

Large global directory. Good for fast RFQs and market scans. Use filters. Vet hard with calls and samples. - Global Sources

Strong trade show ties and verified exporters. Good for consumer electronics and home goods. - HKTDC

Hong Kong Trade Development Council directory and show network. Useful for exporters focused on Western markets. - Made-in-China

Helpful for industrial and machinery categories. Needs strict vetting. - 1688

Chinese language portal with local pricing. Good for idea sourcing and cost baselines. Use a partner for outreach and checks.

Tip: no matter the site, never skip the call, sample, and audit steps. Directories are a starting point, not a guarantee.

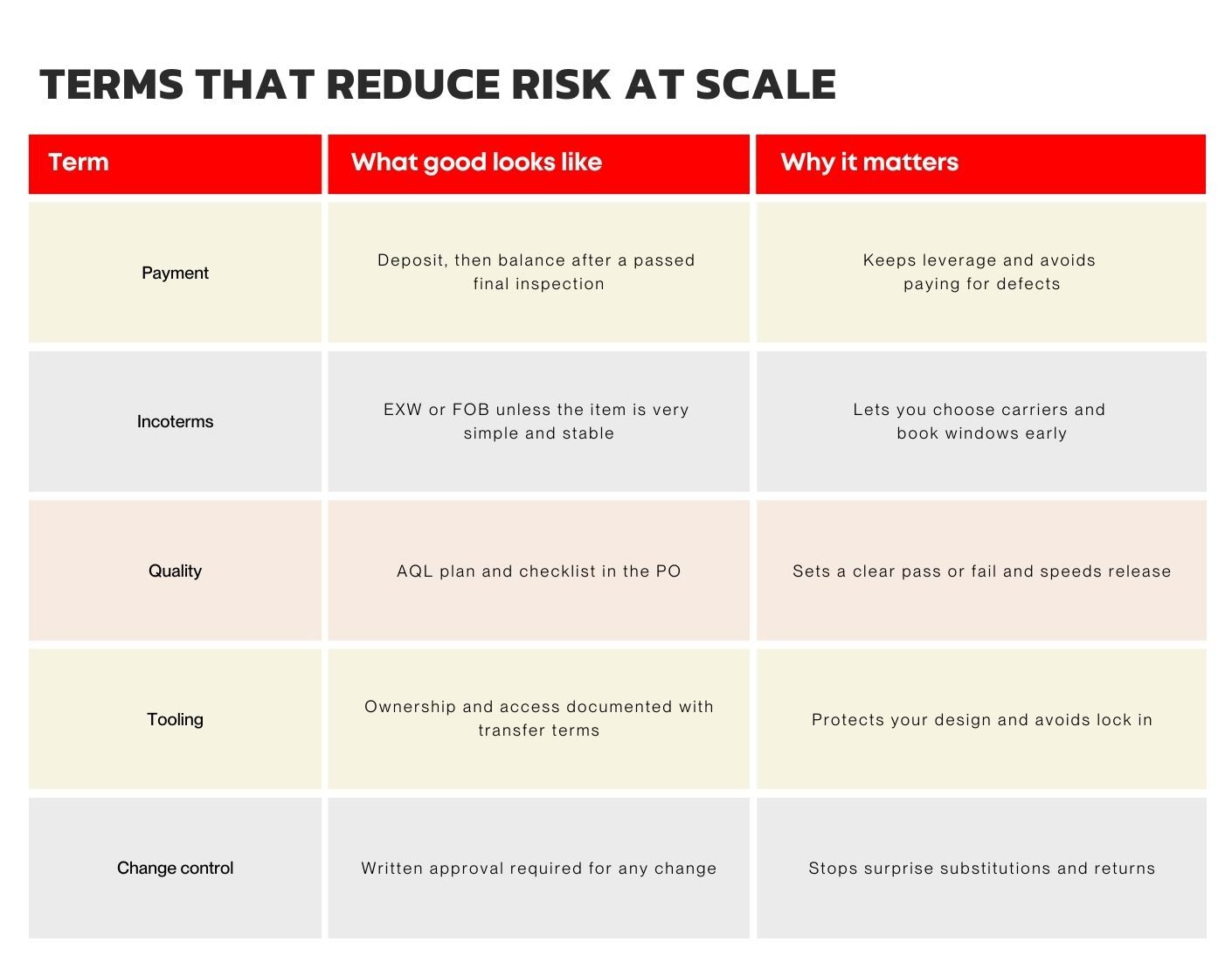

Negotiating Contracts and Payment Terms when Sourcing from China

Price is one line. Protection is many lines. Put key terms in plain language so both sides understand.

Payment terms

Use a deposit with balance after a passed final inspection. For long lead materials, add a milestone when materials arrive. Require a valid tax invoice and a clean packing list before releasing funds.

Incoterms

EXW and FOB keep carrier choice and booking windows with you. DDP can work for simple goods, but you lose routing and cost visibility. Ask for EXW and FOB quotes in the same RFQ so you can compare.

Quality terms

Write the AQL plan into the purchase order. List sample size, acceptance levels, and the exact tests. State what happens if a lot fails. Examples include rework within a set number of days or a price credit.

Tooling

State tool ownership, access rights, storage, and transfer terms. Add a storage period after the last order. Keep tool IDs in your PO.

Change control

No change in material, finish, or process without written approval. Include a simple form that both sides sign when a change is needed.

Common Challenges and Solutions when Sourcing from China

Quality drift

Lock a golden sample. Add during production checks. Tie payments to passed inspections.

Lead time slips

Book long lead materials early. Hold a pre production meeting. Keep two approved suppliers once volume allows.

High MOQs

Ask for a split first run. Offer a firm 12 month forecast. Share reorder triggers so the factory can plan.

Communication gaps

Use visual checklists and short calls. End each call with a written summary that both sides confirm.

Cost creep

Request a cost breakdown by materials, labor, packaging, and margin. Review quarterly. Bank cost downs through packaging and yield gains.

Compliance misses

Define tests by market before the PO. Save test reports by SKU. Block shipment until reports are present and valid.

Education tip: every fix above should live in your standard operating procedures, not just in email.

Shipping and logistics that match your margin

Choose air or ocean based on margin, timing, and shelf life. Book space early for peak months. Since schedule reliability has been in the low 50s, add buffers for port cutoffs, vessel rollovers, and transshipment dwell (Sea-Intelligence). Keep quotes current because routing shifts can move rates quickly (Business Insider citing Drewry). Use carton level barcodes and clean master labels to speed receiving at your 3PL. If the United States is your main market, place bulk stock in a U.S. warehouse on each coast to reach most buyers in 2 to 4 days.

Read more on China Air Freight vs. Sea Freight: Which Is Better for Your Business

As long as you approach sourcing with clarity and the right partners, China remains the most powerful supply chain engine in the world.

Lansil Global helps ecommerce brands simplify product sourcing, factory communication, quality control, and global fulfillment. With our insight into China’s suppliers, we balance quality and pricing so you never compromise. Source from our network of 2,000+ vetted suppliers, supported by an on-the-ground bilingual team at our Shenzhen warehouse. From manufacturing to delivery, we give you supply chain solutions that bring reliable products and good value.

We scout and vet factories, run audits, manage AQL checks, and ensure packaging is secure. Bulk shipments move by sea, urgent units fly when needed, and inventory is stocked in our U.S. warehouses in Pennsylvania and Nevada for 2 to 4 day delivery. You get one plan, one dashboard, and stable landed costs.

If you’re planning your sourcing game plan for 2025, share your target price, sample photos, and first order size. Through our factory connections, we line up suppliers, set timelines, map quality steps, and create an air plus ocean shipping plan that protects both speed and margins. Contact us for your sourcing plan and get one clear roadmap from factory to delivery.